We design thermal air purification devices:

Catalytic oxidizing devices (DKT) – are used to clean exhaust air from industrial processes at low temperatures of the combustion chamber. The catalysts are each time selected individually to the specific case of demand. Thanks to the use of highly efficient plate heat exchangers, it is possible to operate the device with a low concentration of organic solvents, even without burning additional fuel. Catalysts are most often used in the pharmaceutical and chemical industries, as well as in all kinds of paint shops.

Catalytic oxidisers (catalytic oxidisers) are used in many industries. These units are considerably smaller and lighter than their thermal counterparts and therefore require relatively little space for installation. An unquestionable advantage is the flexibility in the choice of the supply heating system. By using an electric heater, we can eliminate NOx emissions. By using a catalytic converter, it is possible to significantly reduce the operating costs of the system while maintaining a very high air purification efficiency. Catalytic converters, catalytic afterburners are used most frequently in the pharmaceutical and chemical industries, as well as in all kinds of paint shops.

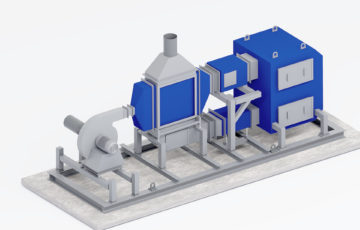

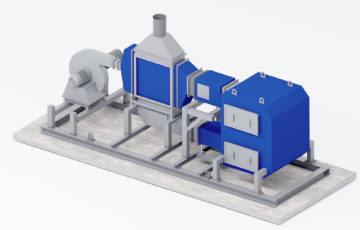

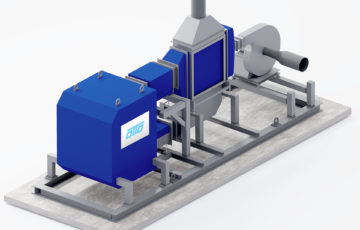

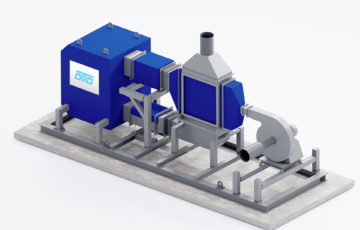

Catalytic oxidizing device DKT

Application:

- intaglio and flexographic printing houses

- chemical and pharmaceutical industries

- painting and coating equipment

- automotive industry

Features and advantages:

- individual design and appearance of the device

- for air flow rates up to 4,000 Nm3/h

- use of proven (proven) catalysts for temperatures from 200 ° C

- heat recovery rate in the device up to 85%

Please send inquiries regarding cooperation to the following address: rzeszow@ottoindustries.com.pl or via the contact form available on the website in the Contact us tab.