We design thermal air purification devices:

Regenerative thermal oxidizers (RTO) – are used to purify exhaust air from industrial processes with the use of ceramic heat accumulators. The use of thermal oxidizers guarantees economic operation, regardless of the concentration of pollutants in the air, also at very high air volume flows. Due to the use of a regenerative, ceramic heat accumulator (heat accumulator), operation is possible without burning additional fuel, even at low solvent concentrations at the inlet to the device.

Through the use of a regenerative ceramic heat accumulator, operation without burning additional fuel is possible even at low solvent concentrations at the inlet to the unit (so-called autothermic process). The safe, robust design guarantees our customers the proven technology they need, tailored to individual project conditions. By using a regenerative ceramic heat accumulator (heat reservoir), operation is possible without burning additional fuel, even at low solvent concentrations at the unit inlet.

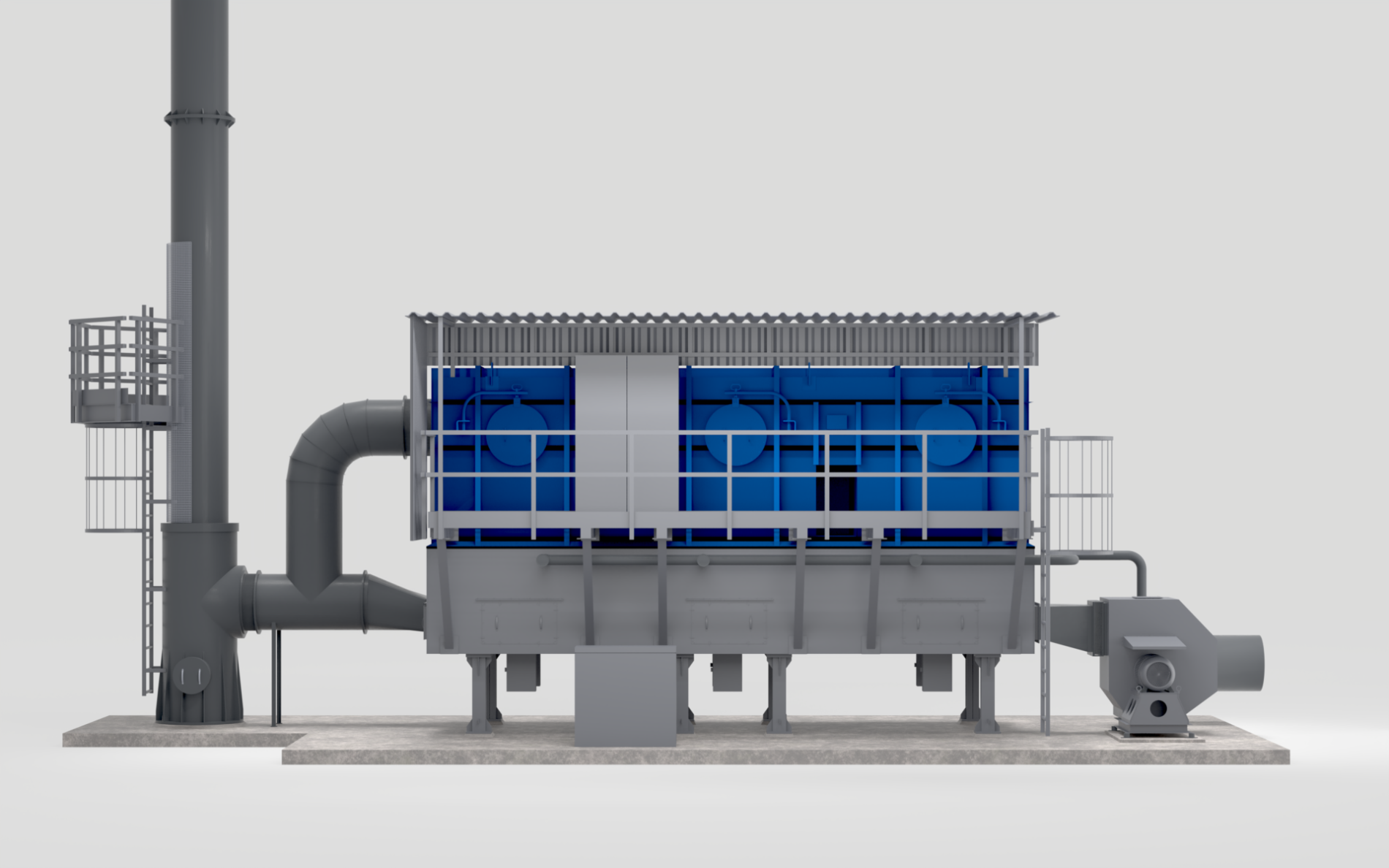

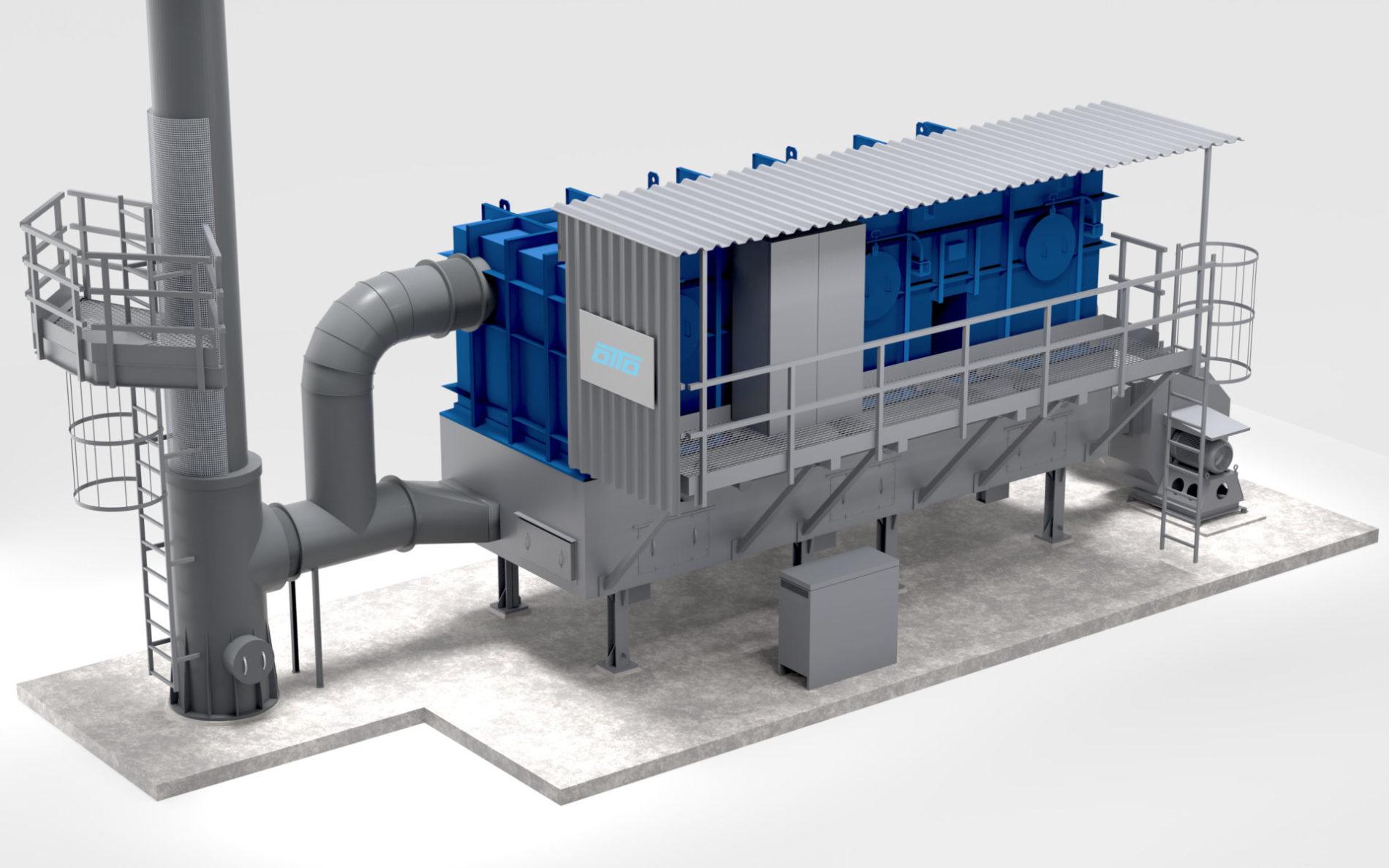

Regenerative thermal oxidizers RTO DRT 2K

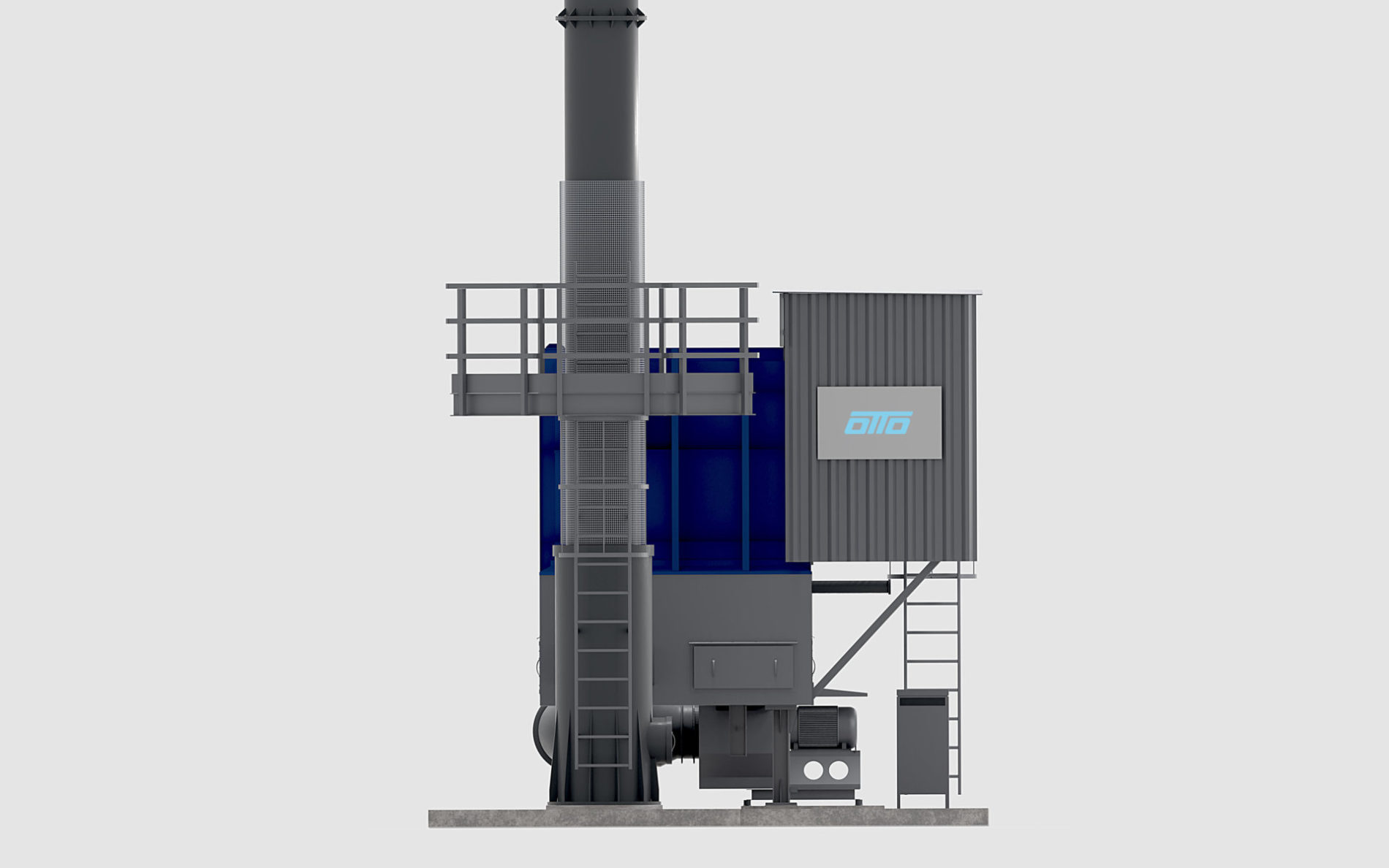

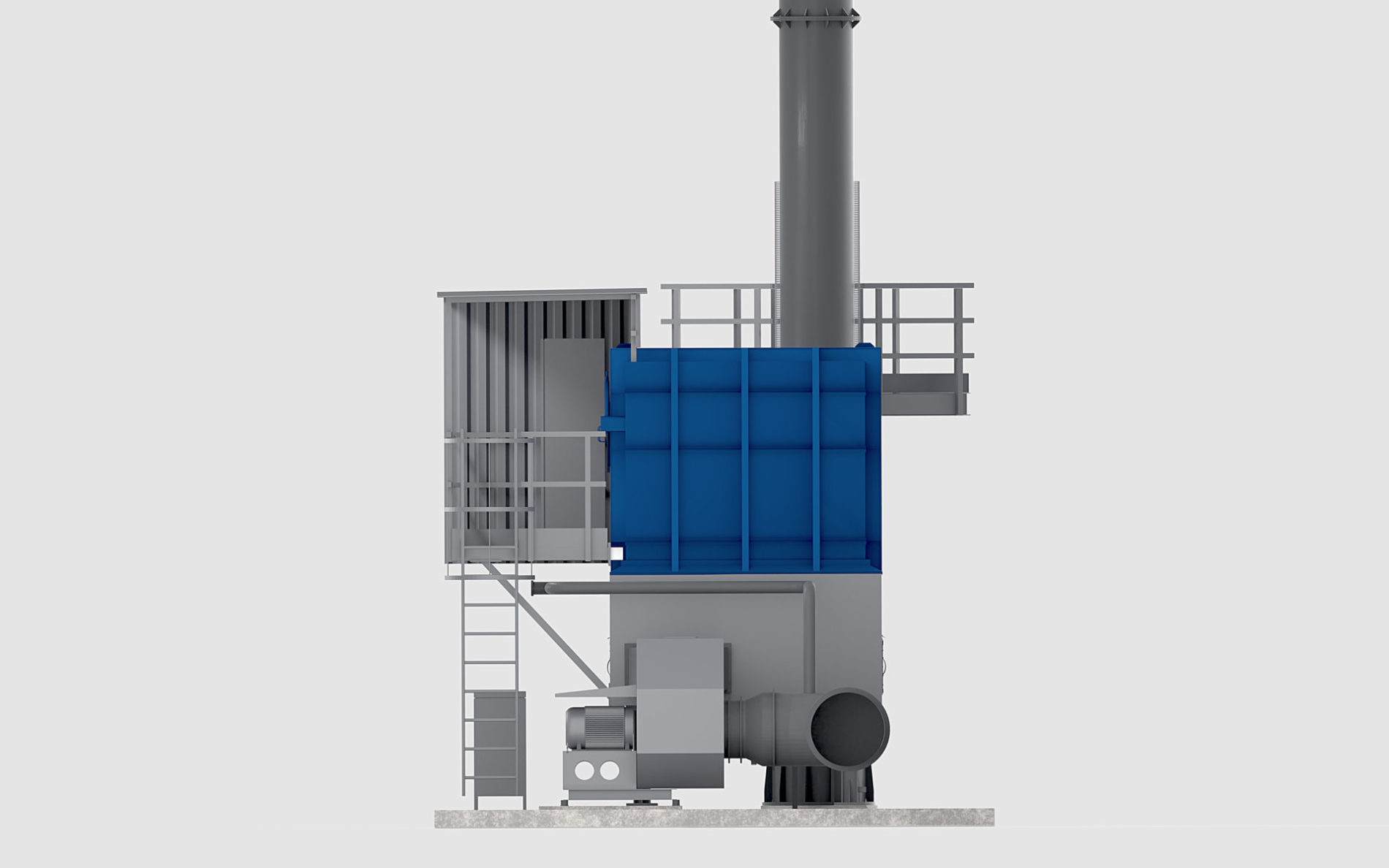

Regenerative thermal oxidizers RTO DRT 3K

Application:

- all production types that emit volatile organic compounds

Features and advantages:

- two-, three- or multi-chamber devices

- for air flow rates up to 200,000 Nm3/h

- heat recovery rate in the device up to 97%

RTO regenerative thermal oxidiser for the benefit of the environment

The thermal afterburner is a device that makes a significant contribution to the environment. By reducing emissions of volatile organic compounds, it also reduces greenhouse gas emissions. Cleansing the air of harmful compounds is another of the advantages that makes the investment in a thermal oxidiser worthwhile – in the long term, the device not only cares for the planet, but also for the health of its inhabitants, which is why it is an essential piece of equipment for the installations of companies wishing to meet all air quality standards. At the right operating temperature, RTO thermal afterburners allow the ideal balance to be found between trace VOC emissions and acceptable nitrogen oxide emissions.

RTO afterburner – a cost-effective device

In addition to its main function of cleaning the air, the RTO afterburner also allows for the efficient reuse of flue gases, making it above all an economical device that allows for significant savings in energy costs. With the RTO afterburner, there is virtually no need for additional fuel to drive the process equipment from which the contaminated air is extracted, which is particularly important for large production companies and industrial plants. The integrated heat recovery by the RTO afterburner allows a significant reduction in production costs compared to other air cleaning methods.

For the comfort of our clients

The main advantage of the RTO afterburner is the function of controlling emissions of pollutants into the air, as well as the possibility of reducing unpleasant odours emitted from various production processes. We guarantee a full range of services from advisory, design, implementation and after-sales servicing of your company’s air purification equipment. Together with you, we will design a solution tailored to your capabilities and needs. We will advise you on how to economically and ecologically exploit all the possibilities of the RTO thermal afterburner and how to adapt it to your company’s existing equipment. Feel free to contact our team of experienced specialists.

Please send inquiries regarding cooperation to the following address: rzeszow@ottoindustries.com.pl or via the contact form available on the website in the Contact us tab.